Display output Data |

In case of using microcontrollers display output data can be a part of electronic devices in which the microcontroller or on a separate device. For this purpose, it can serve a set of signal lights, the display of numerical values as in the calculator display (LCD) or a complex system based on the representation of data on a monitor. If you monitor the process carried DCS display will be on his monitor.

If the image data is used only for the production of state of the process is done completely on fully closed on-line inspection system. The off-line inspection system man decides based on display whether the process of managing the actuator will not do either. It's possible to allow a man and intervention in the on-line system. Specifically, in the supervision and management of a very complex process is not possible to foresee all the possibilities that could occur in real life and therefore human intervention required. For example it is not possible to predict what a stray animal to make a stroll through the plant electrical distribution system.

So, by way of human intervention in the system for handling some of the process may be talking about:

In the first case it is a system that does not have a closed loop control, while the other two closed loop control. Control is the term for simpler cases of supervision and management of the complex, and there are the main microcontroller.

Adaptation of the executive device

How different processes using different operation systems are unable to talk about them in general. Somewhere will be an electric actuator, hydraulic somewhere or something else again, and all different in size, character, conduct and effective, even if this type of energy they use. Most often this will be some sort of electrical excitation of the executive unit sizes.

How is the output from the D/A converters mostly standard, it is clear that each separate system to monitor the process to have a different device for suiting the executive device. Executive management devices very differently. Somewhere in the response to the excitation be almost immediate and will last anywhere seconds. Somewhere will be required power in watts and somewhere in megawatts. The simplest is to manage the executive device as a relay. One bit of digital data is sufficient to manage him and adaptation between the relay and the output from the D/A converter can be a single transistor as a current amplifier. It is certain that the hydraulics to raise and lower the ramp to enter the vehicle to the boat to have a lot of complex elements in the device for adaptation.

An example of a typical standard control unit over a process described in the chapter on microcontrollers is now described in detail. But still it comes to the lowest level of process control. To consolidate several individual control processes in a way to realize their potential of centralized monitoring and coordination of the entire system as a single entity commonly used hierarchical model of process.

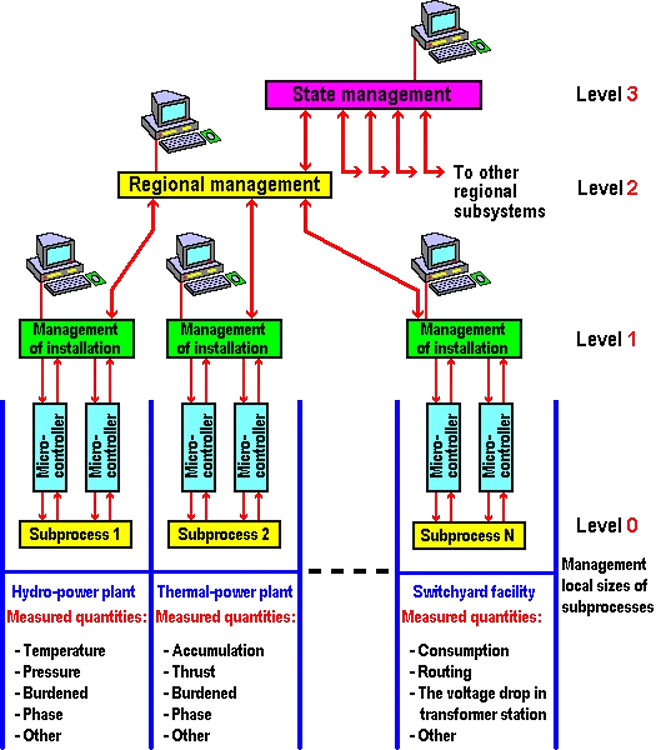

This model can be applied to the manufacturing plant, factory, or even more complex system at the level of the region or state. So, the entire process of managing a system of smashing into the lowest levels of basic sub-processes so that follows the upper grades each subsequent adjusted prior to its affiliates. The best example from everyday life is a system of electrical distribution.

Example I

Conduct electricity production in the energy system of the state.

|

|

| Figure 7.3.2 The system for producing and distributing electricity. |

System for the production of electricity consists of a series of very different plants: hydroelectric power plants, thermal power plants, switchyards, substations and other. Each plant has, except for the regulation of local processes and local coordination or management of computer-aided process (level 1). Besides regional control center (level 2) coordinate the work of local plants in their area. He in turn is associated with state coordination center that integrates management of all regions (level 3).

The above three levels have a direct impact on the local plant in terms of control of individual circuits. It only works on the first level computer. Regulators at the basic level (level 0) managed directly with actual processes such as monitoring temperature, load, phase, power, energy, etc.) according to the principles presented in Figure 7.3.2 Operation of any local plant sufficiently defined and simple, so you can use the automatic management, and the zero level microcontroller manages individual elements of a child process using sensors and executive devices and the computer at the first level, fully managed facility coordinating the work of individual microcontroller. Not only serves as an aid leader is the case with higher level computers.

So, the first control level delivers the next level not only basic information but also parameters derived (calculated) from the basic data. It is possible that all of these monitors and third level. But such a lot of information in one place could be in crisis situations lead to confused decision-making because of the general forest data not see global state system. Therefore rather applies a hierarchical model as shown. According to each successive level is sent to derived parameters obtained from the basic parameters of the level that processes them. General state of the system is what is most important for the system to be able to trace it to make right decisions.

SUMMARY:

From the above it is clear that with the help of microcontrollers cheaper to exert control over the system, if everything is designed specifically for this system. These are generally systems that monitor the production process or processes in the product (car). In a case axis system to be used in the laboratory requirements for flexible multiple devices will become more expensive overall system control over the process. Microcontroller will not be enough, but will need a digital computer with complete program support.

The aircraft is a very interesting example of where you can find all that we have said in all the possible variants. Various parameters are measured directly and some are showing more directly derived from harvested. A good example is the artificial horizon, the pointer on the plane that indicates whether the position of the aircraft in space with respect to its activities and environment are acceptable.

|

Citing of this page: Radic, Drago. " Informatics Alphabet " Split-Croatia. {Date of access}; https://informatics.buzdo.com/file. Copyright © by Drago Radic. All rights reserved. | Disclaimer |