Auxiliary functions - CAM |

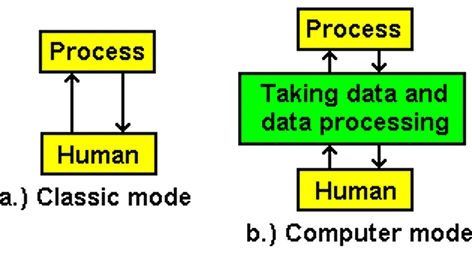

Auxiliary functions that digital computers can work are so numerous as to be almost impossible to systematize and divided by types or tasks. Basically their task and work are the result of the imagination of their builders. But it is certainly greatly help to man for any action of some process. The way a man approaches the process is shown in the following figure.

|

| Figure 7.3.4 Working without and with digital computer. |

First, the conventional method of data processing when the same man is reading, writing and additionally some mathematical methods or similar is almost a thing of history. The computer is now so present in everyday human life and they did not even know, especially the younger generation. Only when the computer fails for some reason understand to what extent he is missing.

Digital computer, the process takes the information and processes them and shows a man in a way that can be decided on the basis of these data on further action. All this happens in a 'moment' without paper computation and use of the mighty time. Processed data, if it is not done at the same time they are so useless as if there was no treatment. In case of delayed intervention in the process it may happen that the process is already in such a state that it would be better if there is no intervention.

In the category of auxiliary functions belong to the following processes:

Display of measurement and other data today is a special technical discipline. These data were not obtained directly from the process, but they are raw materials for processing in order to get the second derivative data that describe the process for a man on a lot more accessible way.

Automatic setting measurement ranges and parameters is best illustrated by the previous example, the measurement of thermal power. It is almost impossible for something so done 'by hand'.

Statistical analysis essentially boils down to the fact that a large number of ways of measuring the statistical distribution and reject all those results that deviate from the mean value by more than a predefined amount. Specifically, it will surely be inconsequential data that are the result of external influence of some current problems. If using multiple sensors in the same process, the result of this process is credible.

Automation of measurements, for example, the case only when the computer asks the size to be measured, and when the 'catch' automatically adjusts the measuring area and monitored its changes. Similar to the above work arrangements for automatic positioning of TV channels and the monitoring of its operating frequency.

An example of the data is present in every store. Almost no product is no BAR CODE by which they can track sales, portable readers perform inventory of goods in a store and warehouse or some similar deals. In addition, in terms of direct monitoring of the process, recorded data can be used to analyze one previously incurred incident to comprehend the causes of its emergence.

There are many examples, especially in the manufacturing facilities of large companies. If you are writing a text is viewed as a process, a computer program with the support of Microsoft Office and the type and how much help. Text can be moved, grammatically checked, display with desired letters, insert an image, save it in another format, etc., and small appliances, such as personnel data compression will allow condensed and written over a dozen times and enable efficient transmission of data electronically post. All stated almost two decades ago that was not possible. Old printer machine is part of a history that will never be repeated.

SUMMARY:

The use of computers in the on-line monitoring of manufacturing processes has become an indispensable part of modern production, without which you simply can not produce by world standards, and from it derived the name CAM (Computer Aided Manufacturing), shorter manufacturing computerized. Not only are present in the production process but also in the products themselves.

Modern ships are full on-line system. The number of crew required to sail the ship all day lower. Today, a large ocean liner can lead a dozen people. On-line systems on board take care of everything: monitor the operation of the machine, position the ship almost to meter, monitor cargo and ballast tanks, they care about keeping the default rate and route, controlled climate chambers and much more. Should describe what is a modern plane?

Even oven for cakes, which are used by our grandmothers are not surpassed. With several types of heaters, barbecues with a motor and some electronics alone will ensure that the installed base of software baked cake or chicken best you can. Truth is not an on-line system, but a man happy.

|

Citing of this page: Radic, Drago. " Informatics Alphabet " Split-Croatia. {Date of access}; https://informatics.buzdo.com/file. Copyright © by Drago Radic. All rights reserved. | Disclaimer |