7.11. Electric car (BEV) |

Firm 'Tesla Motors' from the U.S., California (Silicon Valley), established in 2003. years, presented in 2008. year the 'Tesla Roadster' (Figure 7.11.1b) first commercial electric car powered by an electric motor to power from the battery is converted into kinetic energy, and that as such there are no harmful emissions - BEV (Battery Electric Vehicle). Basically, retained the concept of driving and the transmission of engine power to the wheels as a conventional car (steering, brakes, differential ...), except that is a electric motor drive unit instead of the gasoline engine, and is used with numerous innovations that are available thanks to modern electronics, what leads the use of the computer that monitors and / or manages a number of systems installed in the car. The engine has an efficiency of 90 percent (80 percent at peak load) and develops around 200 kW and can reach speeds up to about 200 km/h and reaches the 100 km/h for 4-5 seconds. Energy is stored in 6831, lithium-ion batteries through an external power adapter for the full 3.5 hours. Their lifetime is 7 years or 170'000 km. With fully charged batteries can cross the path of about 350 km, depending on driving style and braking mode, because the car has regenerative braking, which means that whenever the brakes accumulate some energy back into the battery.

Firm 'Tesla Motors' from the U.S., California (Silicon Valley), established in 2003. years, presented in 2008. year the 'Tesla Roadster' (Figure 7.11.1b) first commercial electric car powered by an electric motor to power from the battery is converted into kinetic energy, and that as such there are no harmful emissions - BEV (Battery Electric Vehicle). Basically, retained the concept of driving and the transmission of engine power to the wheels as a conventional car (steering, brakes, differential ...), except that is a electric motor drive unit instead of the gasoline engine, and is used with numerous innovations that are available thanks to modern electronics, what leads the use of the computer that monitors and / or manages a number of systems installed in the car. The engine has an efficiency of 90 percent (80 percent at peak load) and develops around 200 kW and can reach speeds up to about 200 km/h and reaches the 100 km/h for 4-5 seconds. Energy is stored in 6831, lithium-ion batteries through an external power adapter for the full 3.5 hours. Their lifetime is 7 years or 170'000 km. With fully charged batteries can cross the path of about 350 km, depending on driving style and braking mode, because the car has regenerative braking, which means that whenever the brakes accumulate some energy back into the battery.

'Tesla Roadster' has leather seats, air conditioning, electric windows handling, passenger protection on capsizing chassis designed to absorb impact energy during the collision, friction wheel control, ABS and more monitoring and adjustments that have the modern luxury cars. Before starting the car on a touch screen monitor near instrument table and steering wheel, shown in Figure 7.11.2b, you need to type in a PIN (Personal Identification Number) and then the car is available to the user. Also it can be configured to work in a kind of energy-saving consumption (safe-mode) with which it can reduce its top speed and extend the reach and protection of all settings with a PIN. The touch screen monitor, as shown 7.11.2b, not just for typing the PIN, but to display a large amount of data, the current status of the battery to the speed of the drive, and the user indicates some possible malfunctioning or worn parts, such as warning of worn brake pads, etc.

The following Figure 7.11.1a shows the basic elements of control and power and transmission. Under the ' 1 ' is marked by a group of lithium-ion batteries that can fill up to the declared value of a current of 70 A at a voltage supply of city power grid via an external adapter. Sixty-nine batteries are connected in parallel to form an energy block. Ninety-nine blocks are connected in series and packed in a flat pack, nineteen of those packets are inserted into a common chassis, and all together it weighs about 500 kg. Lithium-ion batteries are hardly charging at low temperatures, and is intended to be warm if the weather conditions are unfavorable. As the development of electric cars got more importance than the former, we can expect a significant development of the battery in terms of smaller dimensions, higher capacity and faster charging.

|

|

| Figure*** 7.11.1 Units of car / Roadster / S / X. ( + / - ) |

Power converter ' 2 ' (Power Electronics Module) is used to using a computer in which is of course some kind of program support. DC battery voltage into a three-phase AC electric motor by using the operating voltage of 375 V with power up to 900 A. The computer and its software in front of the car, built-in control panel, and for handling it serves touch screen monitor. The car's computer monitor his condition, coordinate all necessary actions and respond to changes in external conditions by issuing appropriate orders driving energy unit and other embedded systems that enable greater driving stability and safety of passengers.

The most important part of the power converter is electronically switched semiconductor field consisting of six switches are grouped into three pairs. Each switch is composed of fourteen bipolar transistors (IGBC - Insulated Gate Bipolar Transistors). Their overlapping realizes a three-phase power source required for the electric motor. Is switched over to 32'000 times per second the monitor control system with two processors, primary-working that monitors rotating magnetic field and the secondary-safety who oversees the pressure on the pedal 'gas' and the rotation of the wheel and adjusts them.

PEM with its processor controls the events when the car is running. The processor monitors the accelerator and uses the information to control motor current. To ensure that the generated torque that is appropriate for the condition of the car, or other components in the car, and used other processors outside of the module. For example, if the specified processor and processor that monitors the battery condition to calculate the battery is full, regenerative torque is reduced and if it is detected by the sensor processor is the engine driven ideal temperature, motor current is reduced.

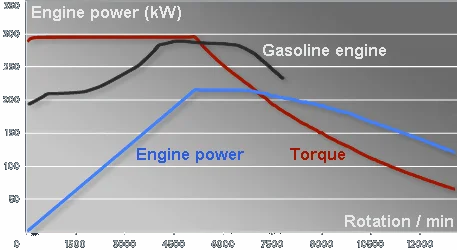

Position ' 3 ' in the figure represents a three-phase asynchronous electric motor (as shown 7.11.2c), no collector and brushes of course, as we now use all electric locomotives, cranes and the like. How to change speeds, through sensors that information is provided by the computer power converters give order that the operating frequency of the three-phase voltages should be used, and achieving a fairly large torque, linear in a wide range of engine as shown in Figure 7.11.2a. In this way, realized that the engine is energy efficient because its rotor spinning in a rotating magnetic field of the optimum speed of rotation, in accordance with the rotation drive wheel axle. The engine consists of a 'cage' rotor (no coil wire) and the stator windings arranged in four half with three sets of coils in each half according to the three-phase electrical system. Changing the phases in the two sets of coils, which is accomplished electronically via the aforementioned switch, the motor rotates in the opposite direction.

The motor is directly connected to a speed-reducer gearbox and differential, Position ' 4 ', above the rear-axle drive wheels. Ease with one gear ratio reduces weight and eliminates the need for complicated mechanism of clutch. Elegant motor is not complicated to run reverse. The engine is simply moving in the opposite direction, according to the order addressed to the instrument table. The early versions of this car had a transmission with two speeds about better utilization of available power, described by the diagram in the following figure.

|

|

| Figure** 7.11.2 Torque and power / Monitor. ( + / - ) |

Development of the power converter and program support was obtained equal power in a wider range and the need for a two-speed gearbox, as it was originally designed power transfer, proved superfluous. Vehicle body is made of a lightweight but strong and hard carbon panels with molded chassis of special type of aluminum, in order of first to offset the weight battery block.

Thus, the concept of management and power transmission compared to conventional cars are basically unchanged, except that the 'engine' of another nature. Differential and drive axles to transfer power to the rear wheels is still a necessity, but we used all the modern developments regarding the achievement of the various controls. Only the ability to manage separate motors for each wheel will contribute to simpler mechanics and an entirely new approach to transfer power to the wheels. In this sense, develop versions that use of the electric drive axle to the wheel or the electric motor on each wheel as part of his suspension.

Position ' 5 ', but the principle is shown in Figure 7.11.2b, and a monitor control and management system of cars (VME - Vehicle Management System). Management system for a vehicle is used for three main purposes:

One of the biggest advantages of a car is an advanced and innovative software - 'firmware', which at any moment and fine tune the functionality of the car through multiple processor systems. More processors are used for different purposes, for control of driver activities, which can not just take for granted, monitors the operating voltage of a battery controls the operation of the engine, are diagnosed, monitored 'lock' and monitor interactions with touch screen monitor. Different operating systems and programming languages are used to optimize the execution and completion of the selected function. The work of all processors has been consolidated to any monitoring of the status of all components while using the car, exchanging information to coordinate their activities relating to the effective response to changing external conditions.

System for driving a car is like a conductor in a finely tuned orchestra. It allows the driver to be aware of most of the events during the drive. Manages security system, opens the door, according to an alert type 'fasten your seatbelt', 'door ajar' etc. Collects and coordinates data of many processes in order to coordinate the activities necessary for driving. Car management system employs three basic modes of operation; sport, standard or extended reach and cooperate with the process of charging and discharging the battery so as to calculate the ideal and the actual ranges using complex programming algorithm that takes into account the age of the battery capacity, driving style and the way energy consumption.

An additional benefit that allows the 'firmware' is a possible diagnosis of the car remotely. If a user feels that something goes wrong with the car, remote diagnostics allows problem identification and resolution without direct access to the car. You can select the service headquarters regarding wireless communications. Besides 'firmware' is constantly evolving and can be upgraded and new versions as needed 'incorporated' into the car.

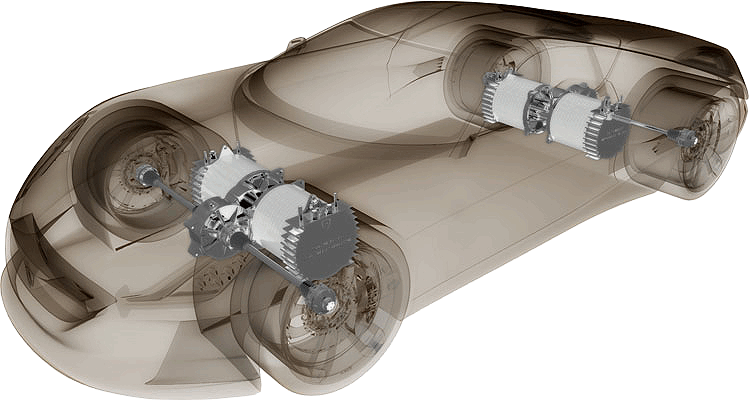

Certainly, this is an electric car for passenger and car model first presented in the series is that this company develops, falls into the category of sports cars, two seaters, and a lot of successful deals with his 'petrol brothers'. In addition to the above new model was developed with more seats, closer to the family's needs, the model ' S ' with five seats and rear or all-wheel traction (Figure 7.11.1c). All-wheel traction is realized with dual motor system. With two motors, one in the front and one in the rear with digitally and independently controls torque to the front and rear wheels. The result is effective traction control in all conditions. Smaller, more innovative and more compact model of the ' X ' (prototype) foreseen with electric motors in three versions, only rear traction, front and rear traction with two separate electromotors, and front and rear traction with separate electromotors for each wheel.

Even ordinary DC motors can outperform any internal combustion engine in almost all areas. Efficiency, extremely fast response, wide range of available power, compact size, regenerative braking and a high torque electric motors only some advantages. An example of successful application of the concept of electric propulsion system that uses synchronous motors with rotor contains strong permanent magnets, called 'Concept_One' is shown in Figure 7.11.3.

|

| Figure* 7.11.3 Prototype of electric car 'Concept_One'. ( + / - ) |

Thus, each wheel is powered by a separate gear synchronous DC electric power of 250 kW. Electric Motors car can 'chase' over 300 km/h, with acceleration from 0-100 km/h in just 2.8 seconds. Battery capacity is sufficient for a distance of 600 km. DC synchronous motor is basically a motorcycle with the collector (commutator) which allows the power supply to the motor rotor windings. Because of the deficiencies caused by the commutator recently developed DC brush less motor that the rotor has strong magnets, while only allowing a current through the stator windings with which computer-controlled electronic circuits through interruptible individual stator windings (electronic switch). In order to properly determine the stator coil through which the electronic commutator miss electricity, how big and what direction, that engine must have a rotor position sensor, based on which a computer controls the engine. This engine produces more power compared to the three-phase motors of the same dimensions. All electric motors supervise computer with software, and therefore a mechanical differential as a mechanism to transfer power to the wheels is unnecessary. Concept of driving with the vehicle is done like conventional car has, by steering wheel.

The car has been developed by the firm 'Rimac automobili' based in Croatia near Zagreb. The car was first shown publicly 2009th years and is the result of a group of enthusiasts, engineers and designers regarding the presentation of an entirely new way of making cars, and it proves that an electric car can be very quick. 'Luigi, the car is faster than the 'Ferrari' :-).

SUMMARY:

Generally, the electric car is not new. Electric drive long ago effectively used for example in small urban delivery vehicles or forklifts or other types of delivery car or storage. Electric locomotives and city trams have long been common. However, an electric car for family use, with a wide network bottler battery (or their quick replacement) is something else entirely, and it is certainly possible alternatives to current gasoline and diesel propulsion systems. Besides its functionality to a large extent, ensure modern electronics, such as computer and its software, without which almost all of this would not be possible to realize.

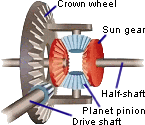

Electric cars of high power electric motor, as well as the racing cars 'Formula E', common to transfer power from one electric motor to the wheels using the differential and axles. Differential is a mechanical device that engine speed that the drive shaft, via a small gear turning a larger gear reduces the number of times that the speed of the drive axle, which are mobile joints associated with wheels aligned to the needs of driving on the road, and that gear subsystem to enable axles and wheels, uneven turning as the car drives bend with an even distribution of power to the wheels. With electric cars less drive power has solutions to the electric motor to the wheel that is directly attached to the rotor of electric motors, electric motor or as part of the wheel suspension. As the motor rotates very quickly, it is necessary to use reducer to reduce the number of wheel revolutions per unit time to an acceptable level. Differential car, either gasoline or electric, with regard to the foregoing reduce speed to the wheels functions as a reducer. If the car high power to each wheel using a separate drive motors, mandatory and must have separate gear for each axle shaft, and on each control torque from the electric motors take care of your computer, the control electronics and software, and monitors the condition of the car and grip of each wheel the substrate and on the basis that performs the necessary alignment of the wheel rotational torque and power transfer to them. Differential as a mechanical device when using a separate electric motor for each wheel is of no importance

Electric cars of high power electric motor, as well as the racing cars 'Formula E', common to transfer power from one electric motor to the wheels using the differential and axles. Differential is a mechanical device that engine speed that the drive shaft, via a small gear turning a larger gear reduces the number of times that the speed of the drive axle, which are mobile joints associated with wheels aligned to the needs of driving on the road, and that gear subsystem to enable axles and wheels, uneven turning as the car drives bend with an even distribution of power to the wheels. With electric cars less drive power has solutions to the electric motor to the wheel that is directly attached to the rotor of electric motors, electric motor or as part of the wheel suspension. As the motor rotates very quickly, it is necessary to use reducer to reduce the number of wheel revolutions per unit time to an acceptable level. Differential car, either gasoline or electric, with regard to the foregoing reduce speed to the wheels functions as a reducer. If the car high power to each wheel using a separate drive motors, mandatory and must have separate gear for each axle shaft, and on each control torque from the electric motors take care of your computer, the control electronics and software, and monitors the condition of the car and grip of each wheel the substrate and on the basis that performs the necessary alignment of the wheel rotational torque and power transfer to them. Differential as a mechanical device when using a separate electric motor for each wheel is of no importance

And other manufacturers are investigated with regard to making an electric car, but apart from the example described none has so far not been available for purchase, but only for rent, and at the end of his simply destroyed. Conceptually, electric cars are similar to other manufacturers described, noting that there are hybrid versions, where the engine drives the generator of a classic power with which it continues to drive electric motors. And still a relatively big problem is the long-time charging the battery, which would imply the concept of rapid replacement batteries for longer trips, and the great weight of rechargeable batteries. Besides, we must develop a network of 'bottling', but the oil industry lobby to great extent hindered the development of electric cars. The reason is probably the fact that the automotive industry is already well based on gas engines, not just in the interest of developing new standards and establish a network of 'filling' on entirely new principles. The rule of oil definitely has delayed widespread use of electric cars. But oil is daily becoming less and less and therefore it is very often the cause of wars. The solution is already long overdue to find. Throughout history they have developed a variety of solutions, even steam (steam piston is very small and powerful, but it is because the horror of the boiler). Although the entire site uses the term 'battery' is actually a accumulator. No doubt it will enhance the development of electric cars and batteries in the concept of making sense of being smaller sized, higher capacity and more effective during charging. Specifically, the charging of the battery takes quite a long time. Seemingly, another 'small' problem is also present. How comes pretty big kW engine power, when you take into account the autonomy of the car and the charging time of the battery, it follows that power consumption during battery charging is not small. How to solve this problem if these types of cars become much more widespread?

And yes, no need to carry any spare parts, not because they are such cars do not break down, but for the fact that the user is simply unable to any treatment except for replacing flat tires or broken bulbs. The only really useful tool is the 'mobile' with possibly already entered service number. In the car is the connector which is connected with a cable to test-device that enables to service via embedded sensors reads all important parameters and establish the general condition of the car or to diagnose malfunctions. Former 'masters' were definitely finished retire :-).

And yes, no need to carry any spare parts, not because they are such cars do not break down, but for the fact that the user is simply unable to any treatment except for replacing flat tires or broken bulbs. The only really useful tool is the 'mobile' with possibly already entered service number. In the car is the connector which is connected with a cable to test-device that enables to service via embedded sensors reads all important parameters and establish the general condition of the car or to diagnose malfunctions. Former 'masters' were definitely finished retire :-).

That an electric vehicles is not a fantasy, but a real reality, confirms the picture right in this paragraph, which represents the 'pump' for electricity in a corporation's garage. Such current connections are used by Cisco, John Hancock HQ, Geico, Hitachi, Sysco and others in the large garages of their corporate headquarters. Not only are the built-in plugs for charging electric vehicles in the garage, but the looks and presence in the garages indicate that the connection form is standardized, which is very important with regard to the use of different electric vehicles. Mass-market electric vehicles have arrived. The industry is being driven by major improvements in battery

technology. As a result, this new and exciting industry of 'charging stations' is here to stay and is expected to grow rapidly.

|

Citing of this page: Radic, Drago. " Informatics Alphabet " Split-Croatia. {Date of access}; https://informatics.buzdo.com/file. Copyright © by Drago Radic. All rights reserved. | Disclaimer |