Computer Printer |

![]() Applying paint to paper in computer technology is the procedure of mixing substances of different colors, SUBTRACTIVE color mixing process, which is reflected in the fact that the reflection of light to the eye of more mixed materials of different colors gives a reflection of different colors. In art it is a well known technique. The computer technique for this purpose is made by mixing substances three basic colors, Cyan, Magenta, Yellow - CMY. For better quality devices commonly used to display additional black substance that is Key element functional black background, and such systems with the addition of black marked CMYK. Shades of black and white is largely represented in the structure of the image and the images in the printing process ensures its loyal print and less use of primary colors. Besides printing 'ordinary' text does not require the use of primary colors.

Applying paint to paper in computer technology is the procedure of mixing substances of different colors, SUBTRACTIVE color mixing process, which is reflected in the fact that the reflection of light to the eye of more mixed materials of different colors gives a reflection of different colors. In art it is a well known technique. The computer technique for this purpose is made by mixing substances three basic colors, Cyan, Magenta, Yellow - CMY. For better quality devices commonly used to display additional black substance that is Key element functional black background, and such systems with the addition of black marked CMYK. Shades of black and white is largely represented in the structure of the image and the images in the printing process ensures its loyal print and less use of primary colors. Besides printing 'ordinary' text does not require the use of primary colors.

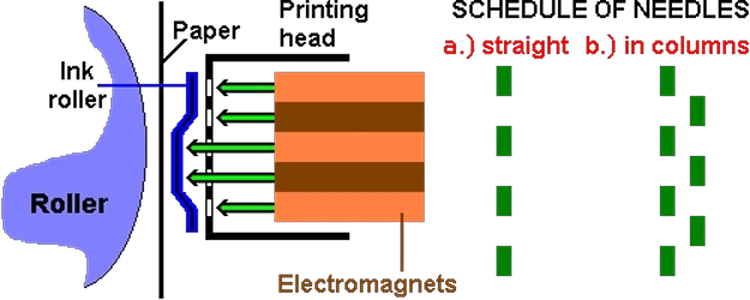

Printers are devices that in some materials, such as paper, a real physical copy of a document or image based on the data in electronic form in the computer. Name of the punch is a general term and better suited for devices in this printing. The printer is an output device that draws on the results of processing paper. Sometimes they worked on the principle of a standard typewriter with a fan which is almost deserted as the solution. One print solutions, based on the concept of matrix display graphemes, the NEEDLE printer that prints the characters by striking pins through the ink into the paper strips (Figure 3.3.33) and sign it as a quick printer accounting services or POS-block printer.

|

|

| Figure 3.3.33 Printing characters using needle printer. |

According ASCII characters received from the computer printer logic determines that the electromagnets will miss electricity to helped push pins against the paper and thus print a single column array matrix. Then head move slightly and the second column lists the matrix sign and so until an entire character. So, in the internal memory of the printer are inscribed binary data matrices for a multitude of characters and the character set that will be used, for example, set the 852 code table for Croatia, by setting the parameters of any printer setting appropriate SWITCH settings, or by entering the printer's EPROM.

Printers are manufactured with the heads of 9 needles in one column (Figure 3.3.33a) to simple printers and quick printers network systems when not required, but the quality of the print speed (DRAFT printing ). Print quality (LQ - Letter Quality) is supplied with the printers of 24 or 48 needles placed in two or more columns are executed so that the next column fills the empty spaces of the first (Figure 3.3.33b). This type of printer does not support printing in color, and it is only possible to take the bar with two stripes along the ink color bands (red and black), but this solution is less available.

Since work on the principle of hitting needle through the tape to the paper, it is quite noisy. Printers using this type of individual sheets inserted into the chamber or 'infinite' perforated paper driven rotating rollers with spikes (tractor) that fits around the perforated section of the paper. Great quick printers of this type can be used A3 format paper, and packaging as well as perforated paper contain up to a few thousands of interconnected perforated pages, or a little less if each page is composed of several layers regarding making copies. Mostly they are already prepared forms such as bank transfer. Very quick and large printers have powerful engines with regard to rapid head movements with needles and paper regarding noise and often have built-in shock and casing that can be shut so that the noise was less.

This type of printer can be applied in accounting services for printing payment order, or the payment of the final balance sheet, as well as small printers for accounts counters in retail shops. Due to today's concepts of limited segment of users, have a relatively high price. According to the previously mentioned it is easy to conclude that the printing is based on the printed ASCII characters, and certain categories of these printers have a record of the marks in their own memory and can not be used in graphics-oriented applications like in Windows. In Windows operating systems page content with vector fonts does not print as ASCII character already printed the whole picture that we see on the monitor. In doing so, it uses a graphical set of instructions that these printers have in essence printed custom graphic image pixels resolution printers. For example, images or pages of text displayed on the screen at a resolution of 800×600 is printed as an image or page of text at a resolution of 180×180 dpi. Understandably, the printing image is black-and-white, low-grade and very slow. Accordingly, the use of this type of printer in the Windows Graphical Environment pointless.

A better solution than needle printer in Windows graphical environment are INK-JET text and image created in a similar way as the needle, but instead of needles on the printhead are small holes through which ink is sprayed onto the paper. They are available in black and white and color printers. Black-and-white printers typically use 50-100 injection nozzles of black ink. Color printers use three (four) head with nozzles for three colors, CMY systems (Cyan, Magenta, Yellow), with blue-green, purple and yellow. Some have additional head with black (CMYK), which has more jets than the others and add to the print quality for black and other colors savings in black print. True, the printers are fairly quiet in operation and are cheap, but the ink is expensive and the ink cartridges are small and can be printed relatively few pages. This is a very expensive way to print if we include the costs required to print one page. Even greater evil is the fact that the colors in the pipes and holes in the dry shut syringe if the printer is not used daily. Besides, although the imprinted color after a while and dry and still have poor resistance to moisture. Special products in this category are printers to produce photographs. Greater precision printing, higher DPI, the higher the price and expensive paper does not make them very attractive product for ordinary computer users.

The best solution is LASER printer. Basic printing technology, used in laser printers has devised another 40 years and was used in the copiers. The essential difference is that the role of the lens and lamps for lighting with copiers over laser or LED light beam with printers. Light beam on the photo-sensitive drum draws the negative image that will be further transferred to the printing paper as a positive. Breakthrough plastic as the base of the casing and the more sophisticated and cheaper electronics have enabled the development of a laser printer as the output unit of the computer, and the application of light-emitting diodes (LED) have been further reduced its price for this type of printer and reduce their size. LED printers are an increasingly popular solution for companies and institutions as well as for the home.

Laser printer as the basis for creating images used roller where the photo-sensitive coating that has the property that it can accept an electrical charge in a small individual electrically unconnected elements drum surface. Electronics printer gets a picture of a computer which then analyzes and converts the negative image and draws it to a raster-display declared the resolution (dpi - dots per inch) printer, and in accordance with the density of elements on the surface of the photo-sensitive drum. If the density is higher, it means that the individual elements of the drum surface and the lower image is a better future. Corona wire-electrode 'K1' shown in Figure 3.3.34a when turning roller compacted surface positive charge roller elements. Surface roller elements are mutually insulated electrical characteristics as a result of the layer applied on the roller.

When charged area occurs in the plane 'S' laser touring roller from point 'A' to point 'B' along the planes 'S', which is made possible by rotating polygonal mirror that in turn changes the position of the beam, which sends a laser, and the beam was rejected by mirrors' moving point 'A' to point 'B' in accordance with the rotation of the mirror. More mirrors a fast beam switch to the starting position and quickly move along straight rays 'S'. Each side polygonal mirror redraws a line of print. When moving the laser beam illuminates or does not illuminates individual elements on the cylinder based on raster-display, thus eliminating the elements of reel or leaves a positive charge, which they get from the wire-electrode 'K1' when you rotate the roller. Positive charge does not go unexposed elements that need to accept powder and paper to black spots.

The positively charged elements of the photo-sensitive drum to accept the powder particles (color, toner), which are negatively charged and placed before the photo-sensitive drum roll leading container of powder. This process is sometimes called because it corresponds with the development process in the photo industry, where the negative development creates a positive image. When the powder particles to the photo-sensitive drum creating a positive image needs to be transferred to another paper. This is again done using an electrical charge. Powder drum is transferred onto the paper using electrically charged wire-electrode 'K2', which pulls the powder particles from the roller toward you and so convey them to the paper that passes between the roller and the wire-electrode 'K2'. Velocity of the paper must be coordinated with the speed of rotation photo-sensitive drum. The image is transferred to paper, but the dust is still not fixed to the surface of the paper so quickly wiped off her. Fixing mechanism is performed by combining pressure heater and heating so that the powder particles are actually pressed into the paper and UPEK what the final print quality makes, precise and highly resistant to external impact.

After the powder was transferred from the roller to the paper, any residual powder on the photo-sensitive drum mechanism will be removed for cleaning and neutralizing the charge on the elements of the roller elements before re-charging roller 'K1' electrode.

|

| Figure* 3.3.34 The principle of laser and LED printers. ( + / - ) |

Laser plots point by point in a single row of labels 'A' to 'B' of the example images with 3.3.34a, and so line by line. LED draws an entire row at once, and by the next line that has since prepared for rendering. Difference in the two approaches is shown in Figure 3.3.34b. Besides LED panel takes up much less space than a laser mechanism which ultimately makes the printer of small size.

No matter which type of laser printer is, the mechanism of photo-sensitive drum with accompanying 'wires' are mainly located in the same chassis (popularly called 'toner'), with the print color and Tank color. When you insert the cartridge into the printer protective cover photo-sensitive drum is shifted to the side to make it allow its lighting and connect 'corona wire's power source. Before using the 'toner' to remove the masking tape that closes the mouth of the container to prevent its paint wastage during transportation. Spent cartridge color change means the casing and thus all other parts of the body. Certain cheaper versions have removable printer cartridge color to the chassis, so it is not necessary to completely change the entire roller mechanism, the electrode and the tank when the tank is empty paint. This concept of separate container color from the rest of the casing is often used in color laser printers to make them more accessible price.

What then is the rest of the print engine cares? Provides generate images for print based on the images obtained from the computer, transfer the image to the photo-sensitive drum, a voltage source for the 'corona wires', transport sheets of paper through the printer via the photo-sensitive drum and delivery of printed materials to you after passing through the rollers ' baking' color

To print in color above procedure is repeated three times for each primary color at a time. For color printers use four (CMYK) or more ink colors to achieve a quality print. In the final process of all colors and inflicted printed on paper, and then baking to give the resulting image resistant to moisture and print resolution of 600x600 dpi up to 2400x2400 dpi or more. Number of pages that can be printed on one tank depends on the size of the tank and the amount of powder (color toner) in it. How much money the music.

For the same type of printer price difference generally makes the amount embedded electronics. Specifically printer normally produces only a USB port, but it can get extra CENTRONICS connector or standard UTP network card. The network card is a very good solution for the integration of resources in one group of users and the printer must then assign the network settings in the same way as the computer on Plans for networking devices some institution or firm. Some printers also support multiple types of communication protocols (TCP / IP, IPX / SPX ...). According to the cost price of the print run to the costs required to print a single page, this type of printing is the cheapest.

Example XIII

What makes a variety of basic colors color monitors and printers?

Monitor to display different colors mixing process uses light rays - ADDITIVE process. For color printers are obtained by mixing substances - SUBTRACTIVE process. These two procedures have the same basic colors to obtain a spectrum of colors. These two ways of mixing colors can lead to problems if the image on the monitor is not compatible with the result of the printer. This alignment comes particularly to the fore in preparation for publication, and that photo printers are increasingly in use in 'ordinary' users, this request is no longer the privilege of professionals. It is necessary to adjust the monitor display with future printing results. For this purpose, shall be available configuration file monitors and printers, to support the program for photo editing committed compliance monitor and printer settings. In the Photoshop for example, the image will be displayed with colors that will actually print. The problem of color matching more in Chapter 3.5.7, in which the emphasis is on the PC computer system.

As the jets smaller and closer to each other than pins, and has a large number of them, the resolution inkjet printer better than a needle (720×720 dpi or more). Besides almost silent in operation since there are no bumps in the paper and producing needle roller printers. Print quality depends largely on the quality of the ink and in particular on the quality of the paper. How are color laser printers are all cheaper and it is expected, and their recent massive use. The advantage of laser printing is considerable resistance to water output, but the newer inkjet printers, designed specifically for printing photos, use modern colors that are not warmed up and are resistant to water, of course, with a special paper.

Some places are still using THERMAL printers that create heat printing paper that changes color on heating. Until recently, on this basis, doing almost all fax devices and POS-block printers for invoicing. One of the versions of these devices is creating print heat strip where you want to leave an imprint on the paper. But these prints fade with time and are not suitable for permanent storage and less encountered in use.

The printer prints and this is a similar device at the printing device, a device that draws lines forming shapes called PLOTTER, the output device is intended for making drawings and sketches, especially of larger size and excellent quality. All drawing work on the principle of moving the pen to draw in relation to the media on which it is drawn. So, have a stylus cartridge with whom write in the paper with one or more colors. An entirely different category of printers. Depending on the design drawing is done by moving the stylus over a stationary paper by its length and width, or wrapping easy-start, step by step, so that the lines are printed one after another. The paper in this case can be rolled. Writing in black and white is simpler than the technique of drawing in color, which must be CMY or CMYK system for drawing. Depending on the type of ink and equipment, drying scribbles by natural means or by heating. Draftsman is basically dedicate specific output device, so the plotters in a project office in the state to draw a picture to A0 format standard paper and are therefore proportional to its size. Opposite them, ECG tracer, the medical device for viewing of the heart, it prints in monochrome lines on paper a few inches wide. Plotters for scientific purposes in turn have some different characteristics. Draftsman as the output device does not fall into the devices general motives.

The printer's resolution is definitely describing its quality. If the printer from the computer sends an image resolution of 1024×768 pixels, depending on the resolution of the printer, on paper it will not be the same size if the image does not restate previously. That the image could be displayed along the entire paper format, should make scaling the original image at a higher or lower resolution and forward the processed image so the printer. Cares about the said driver (driver) printer and its accompanying software. Suppose that the image above resolutions printed on the device display resolution 600×600 dpi (Dots Per Inch), without interpolation image to be printed in size approximately 4.33 cm×3.25 cm. DPI is actually a measure of pixel density per unit length, and surface area of one square inch.

If elements are images of black powder grains, DPI designation is valid, but if it is a color display composed of multiple grains of powder is considered pixel size and then measure PPI (Pixels Per Inch). But manufacturers in the specifications of this printer often identify and printer color often is indicated DPI. The higher the pitch, the image is better and supports more colors and density changes in certain parts of the image as the eye looks brighter or darker colors. Also means that the monitor screen, image processing print density 600x600 dpi and print size A4 images, you should have about 100" diagonal to display the image to be printed, because the density of the monitor resolution of 1024×768 pixels of about 60 dpi horizontally monitor which is a wide screen 17". Density of the displayed image on the screen is much smaller compared to the print density. PPI and DPI are the characteristics that should be respected, and when choosing a digital camera and scanner images that the density of the recorded image and scanning capabilities significantly larger than the monitor screen. Such devices should be selected in a way that DPI is greater than or equal to the highest resolution monitors or imaging facilities that are used.

Specific printer is device for 3D printing. This is a process in which a material such as plastic or some other material combines and merge by layers which are connected together as liquid molecules or granules under the control of a computer to create a three-dimensional object. This device will be described soon as a specific device.

|

Citing of this page: Radic, Drago. " Informatics Alphabet " Split-Croatia. {Date of access}; https://informatics.buzdo.com/file. Copyright © by Drago Radic. All rights reserved. | Disclaimer |